Industrial Coffee Grinder for Bulk Coffee Production: Essential Information

Industrial Coffee Mill Overview: Boost Effectiveness and Top Quality

In the competitive landscape of coffee manufacturing, selecting the ideal commercial coffee grinder plays a crucial role in improving both performance and product high quality. Recognizing the nuances of various mill kinds and essential functions-- such as customizable grind setups and robust construction-- can substantially influence the final taste account of the coffee. The optimization of the grinding process, combined with thorough upkeep, is essential for sustaining performance over time. As we discover these crucial elements, it comes to be obvious that the effects expand past plain devices option, influencing total organization success in means that require closer examination.

Understanding Grinder Kinds

When picking a commercial coffee mill, comprehending the various types available is vital for enhancing both flavor extraction and functional effectiveness. The two primary kinds of mills are blade grinders and burr grinders.

Eventually, selecting the right sort of grinder is important to maintaining high quality and efficiency in coffee manufacturing, making it crucial for businesses to invest in top notch burr mills for ideal outcomes.

Trick Features to Think About

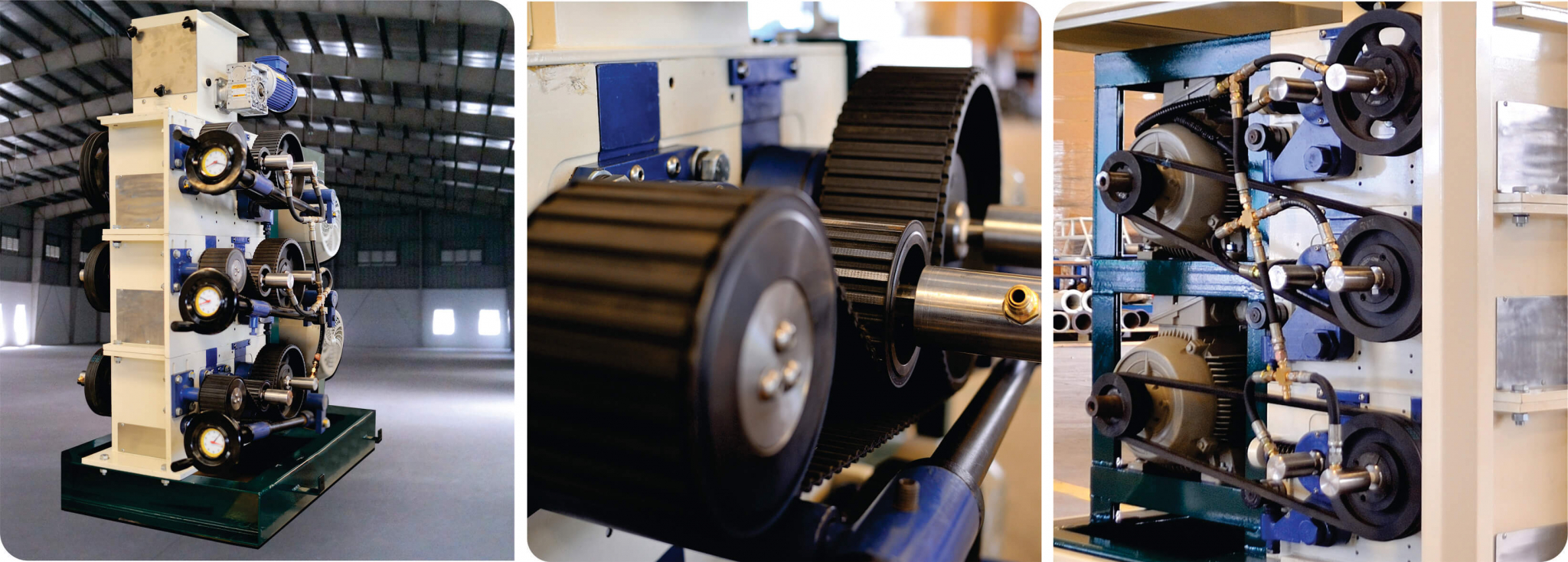

Picking an industrial coffee grinder calls for mindful consideration of a number of vital functions that can substantially affect both efficiency and the overall coffee experience. One of the key facets to evaluate is the grinding mechanism. Burr grinders are generally favored over blade mills, as they provide a consistent grind dimension, which is important for optimum removal and flavor.

Another essential feature is the grinder's capacity. Depending on the volume of coffee you need to process, select a model that can handle your requirements without compromising rate or top quality. In addition, take into consideration the grind settings used. A flexible grinder with multiple settings permits you to customize the work size to different developing approaches, enhancing the coffee's taste account.

The building material also contributes in toughness and maintenance. Stainless steel elements commonly offer durability and are less complicated to cleanse, which is necessary for preserving health requirements. Assess the mill's noise degree, particularly in a busy coffee shop or production setting, where extreme sound can be disruptive. Buying a grinder that stabilizes these functions can significantly boost both operational performance and the quality of the coffee offered.

Optimizing Grinding Refine

To achieve the finest outcomes in coffee preparation, optimizing the grinding procedure is essential. The grind dimension considerably affects removal, flavor, and overall high quality of the made coffee. Various brewing techniques need details grind sizes; for example, espresso requires a great grind, while French press necessitates a coarse appearance. Comprehending the connection in between grind size and developing approach is the primary step in optimization.

In addition, monitoring the grinding rate can enhance the procedure. Slower grinding commonly produces less special info warmth, protecting delicate tastes and scents. Conversely, quicker grinding might generate excessive warm, adversely affecting the coffee's quality.

Maintenance and Care Tips

Proper upkeep and treatment of commercial coffee grinders are necessary for making sure optimal efficiency and longevity. Routine cleansing is the foundation of maintenance; deposit buildup can affect flavor and grinding effectiveness. It is a good idea to clean up the mill after each use, cleaning down the outside and getting rid of any type of coffee grounds from the burrs.

Additionally, evaluate the grinding burrs for wear and tear. Dull burrs can compromise grind consistency, so they must be changed as necessary. Industrial Coffee Grinder. Periodically adjusting the grinder is also important, as this keeps the desired work size for numerous brewing methods

Lubrication of moving parts should be executed according to the producer's specs, as this lowers rubbing and extends the life of the tools. It is essential to make use of food-grade lubes to make certain safety and conformity with wellness policies.

Lastly, maintain the grinder Get More Info in a stable and dry environment to stop rust and deterioration. By sticking to these maintenance and treatment ideas, drivers this content can improve the effectiveness of their commercial coffee grinders while making certain premium output and extended operational life.

Roi Analysis

Assessing the return on financial investment (ROI) for commercial coffee mills is vital for businesses seeking to optimize their coffee production capabilities. A complete ROI analysis helps determine the financial feasibility of spending in top quality grinders, enabling services to consider the preliminary costs against prospective gains.

Evaluate the purchase price of the mill, including installation and any kind of needed alterations to existing framework. High-performance mills typically lead to minimized grinding time and enhanced throughput, which can substantially boost performance.

In addition, take into consideration the influence on product quality. Industrial Coffee Grinder. Superior mills produce a more constant grind size, which can enhance flavor accounts and client complete satisfaction, ultimately driving sales. By boosting the high quality of the end product, businesses can justify greater rates, resulting in increased earnings

Final Thought

In recap, an industrial coffee grinder plays a crucial function in enhancing both efficiency and item quality within coffee manufacturing. Eventually, the critical financial investment in a reputable mill contributes substantially to enhanced income and competitiveness in the coffee market.

In the competitive landscape of coffee production, picking the right industrial coffee mill plays an essential function in boosting both efficiency and product high quality. The 2 primary types of grinders are blade mills and burr grinders. Within the burr grinder group, there are flat burr grinders and cone-shaped burr mills, each with its advantages. Burr grinders are normally preferred over blade grinders, as they give a constant work size, which is crucial for ideal removal and taste.

In recap, a commercial coffee grinder plays a critical role in improving both performance and item top quality within coffee production.